Clone Product & Update Quantity | O2VEND Catalog Management

Learn how to clone products and quickly update inventory quantities in O2VEND. Duplicate existing products with all configurations and manage stock efficiently across warehouses.

The Clone Product feature allows creating a new catalog product by duplicating an existing product with all its configurations, while assigning a new product name.

This helps speed up catalog creation when multiple products share similar attributes, pricing logic, or operational settings.

Cloned products inherit key configurations such as General details, pricing rules, attributes, stock behavior, SEO data, and linked settings, which can be adjusted after creation.

Why Use Clone Product

Cloning a product is useful to:

- Reduce manual data entry during product creation

- Maintain consistency across similar products

- Quickly launch variants or similar catalog items

- Reuse pricing, tax, inventory, and configuration logic

- Improve operational efficiency for large catalogs

How to Clone a Product

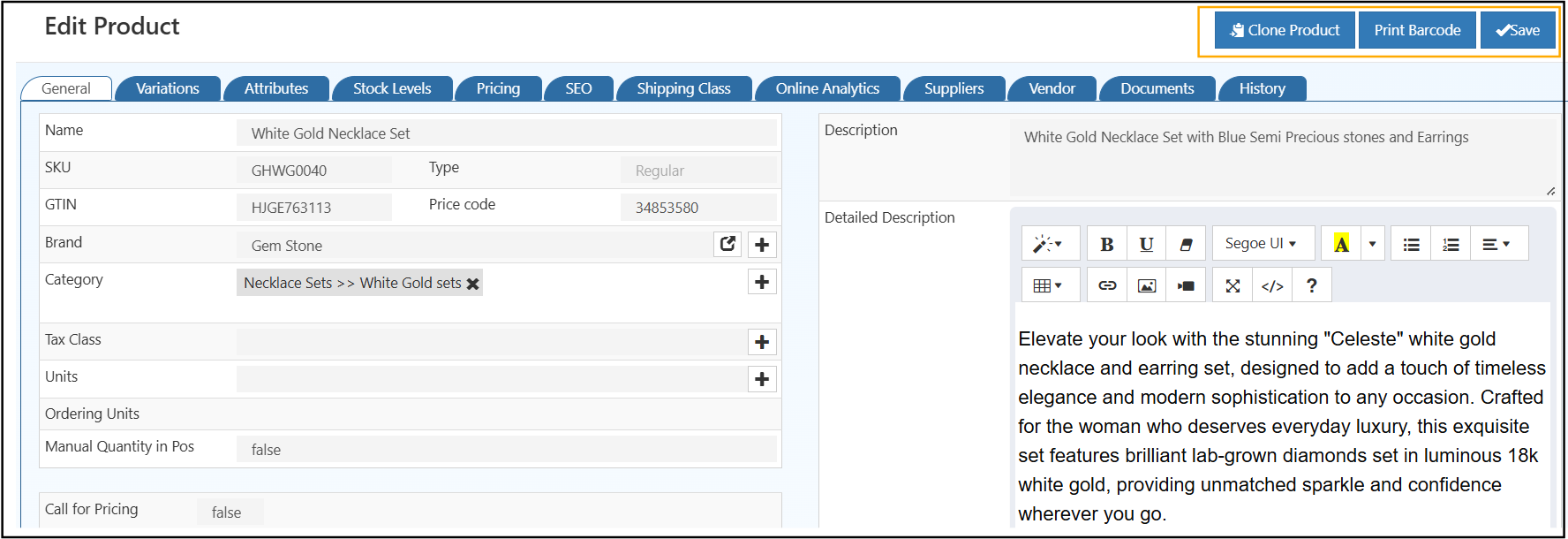

Follow the steps below to clone an existing product:

- Open Back Office

- Navigate to Catalog

- Open the Products section

- Locate the product to be cloned from the product list

- Click the Product Name to open the Edit Product screen

- Click Clone Product from the top-right corner

- Enter a New Product Name

- Click Save to create the cloned product

A new product will be created with the same configuration as the original product.

Tip

Clone products first and update only the required fields such as name, SKU, price, or attributes.

This approach significantly reduces product setup time and ensures configuration consistency.

Print Barcode

The Print Barcode button allows generating and printing barcode labels for the selected product directly from the Edit Product screen.

These barcodes are commonly used for inventory management, POS billing, warehouse operations, and product identification.

Purpose of the Print Barcode Feature

This feature is used to:

- Generate scannable barcodes for products

- Support fast billing at POS counters

- Enable accurate inventory tracking

- Reduce manual product identification errors

- Streamline warehouse picking and stock audits

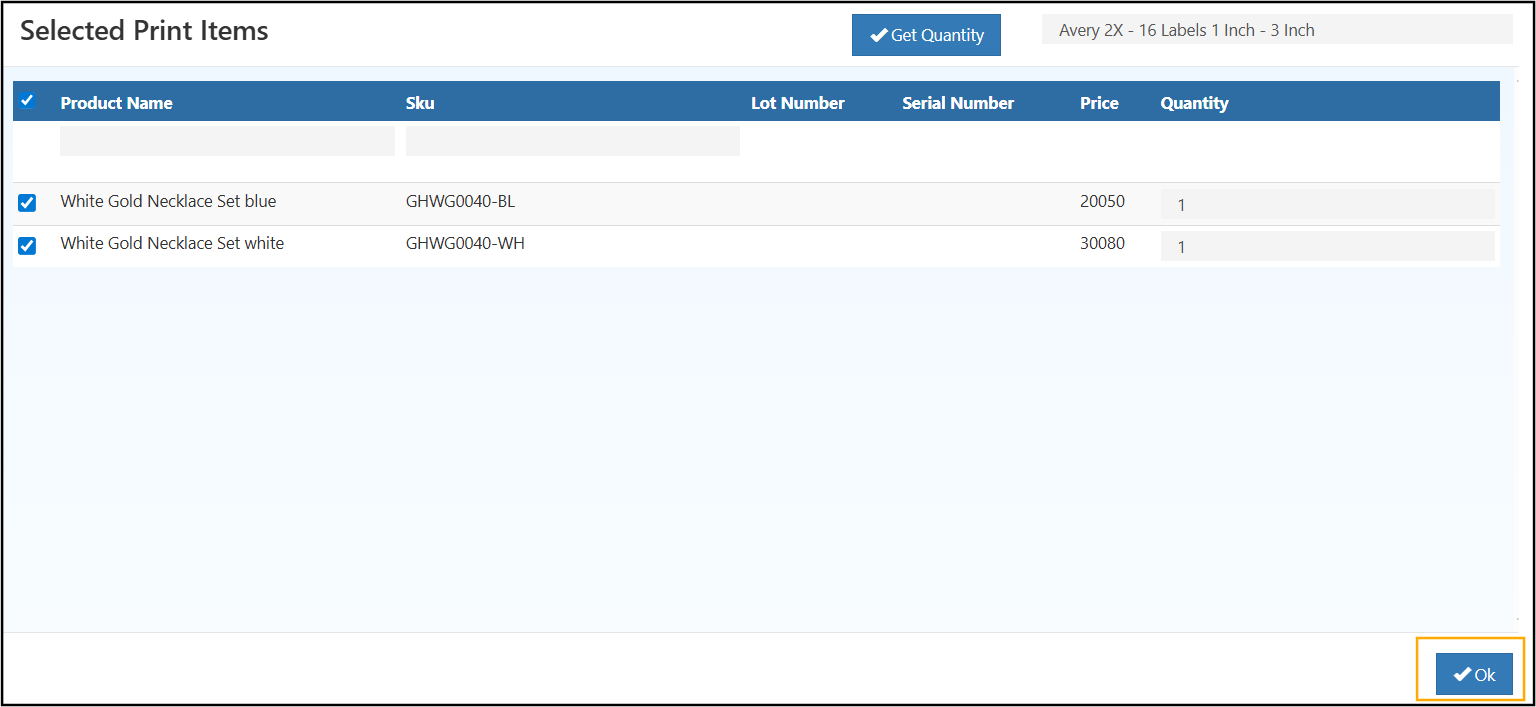

How Print Barcode Works

When Print Barcode is clicked:

- The system generates a barcode based on the product’s unique identifier (such as SKU or internal product code)

- A printable barcode layout is created

- The barcode can be printed and attached to:

- Product packaging

- Shelves or bins

- Inventory labels

Note

Barcode generation is read-only and does not modify product data.

Changes to product identifiers may require reprinting barcodes for accuracy.

Update Product Quantity

The Update Product Quantity feature allows adjusting stock levels directly from the product list page without opening individual product records.

It is commonly used for quick stock corrections, bulk updates, and warehouse-based adjustments.

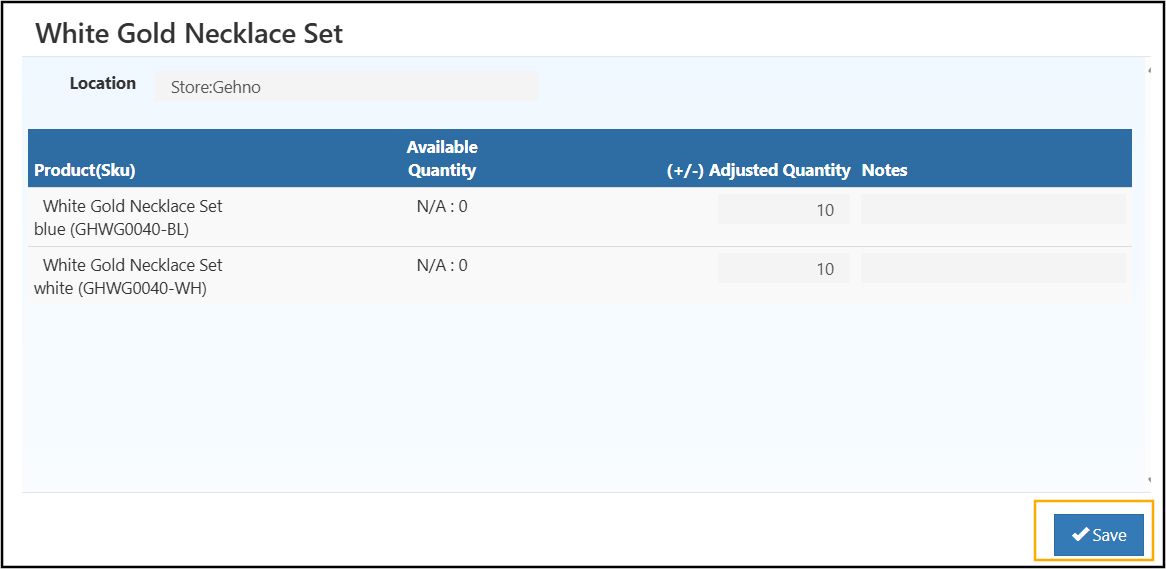

How to Update Product Quantity

Follow the steps below to update inventory quantity:

- Open Back Office

- Navigate to Catalog

- Click Update Quantity

- Select the Warehouse from the dropdown

- Click the edit (✎) icon for the required product

- Enter the Adjusted Quantity

- The adjusted quantity is added to the current stock value

- Enter Notes for audit and reference

- Click Save

The updated quantity is reflected immediately in inventory records.

Operational Notes

- Quantity updates are warehouse-specific

- Notes help track the reason for stock changes

- Adjustments are logged for audit and review

Tip

Use the Export Products option to download product data as a CSV file for bulk review, reconciliation, or offline updates.