Stock Levels - O2Vend Inventory Guide

The Stock Levels feature in O2Vend helps maintain optimal inventory by setting limits for product availability.

Proper stock level configuration prevents both overstocking and stockouts, ensuring smooth order fulfillment and efficient warehouse management.

Stock Levels

Stock levels define how much of a product should be available in the inventory at any given time.

They include parameters like reorder quantity, minimum and maximum limits, and safety stock � all crucial for inventory control and replenishment planning.

How to Set Up Stock Levels

- Open the Back Office.

- Navigate to the Settings menu.

- Under Stock Settings, select Stock Levels.

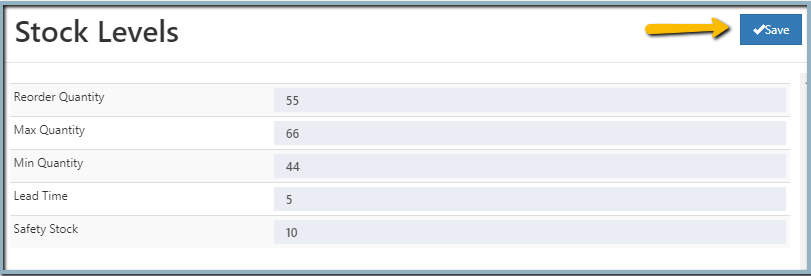

- Enter the required details:

- Reorder Quantity: The quantity at which a product should be reordered to avoid running out of stock.

- Max Quantity: The maximum stock level that should not be exceeded.

- Min Quantity: The minimum stock level below which a reorder should be triggered.

- Lead Time: The number of days required to restock the product after placing an order.

- Safety Stock: The buffer quantity maintained to handle sudden demand spikes or supply delays.

- Click the Save button in the top-right corner to apply changes.

Once saved, these values will automatically apply to newly created or updated products, ensuring consistent stock monitoring.