How to Create GRN in O2VEND (Step-by-Step Tutorial for Stock & Package Management)

Having trouble with stock not updating after a Purchase Invoice in O2VEND?

Inventory in O2VEND only updates when you complete the Goods Receive Note (GRN).

Incorrect or skipped GRN is one of the leading reasons for:

- Stock mismatches in the warehouse

- Audit errors and discrepancies

- Finance and inventory reports not matching

The GRN (Goods Receive Note) is the official inward stock confirmation document.

It verifies supplier deliveries, approves received quantities, and posts them to inventory for accurate warehouse management.

In this step-by-step tutorial, you’ll learn:

- How to create GRN from the Purchase module

- When and how inventory stock gets updated

- Package-level verification and approval workflow

- Tips to prevent stock mismatches and errors

Follow this guide to ensure accurate stock, audit-ready records, and smooth warehouse operations.

Quick Answer: Where Is GRN Created in O2VEND?

GRN is created from the Purchase Invoice Edit Page.

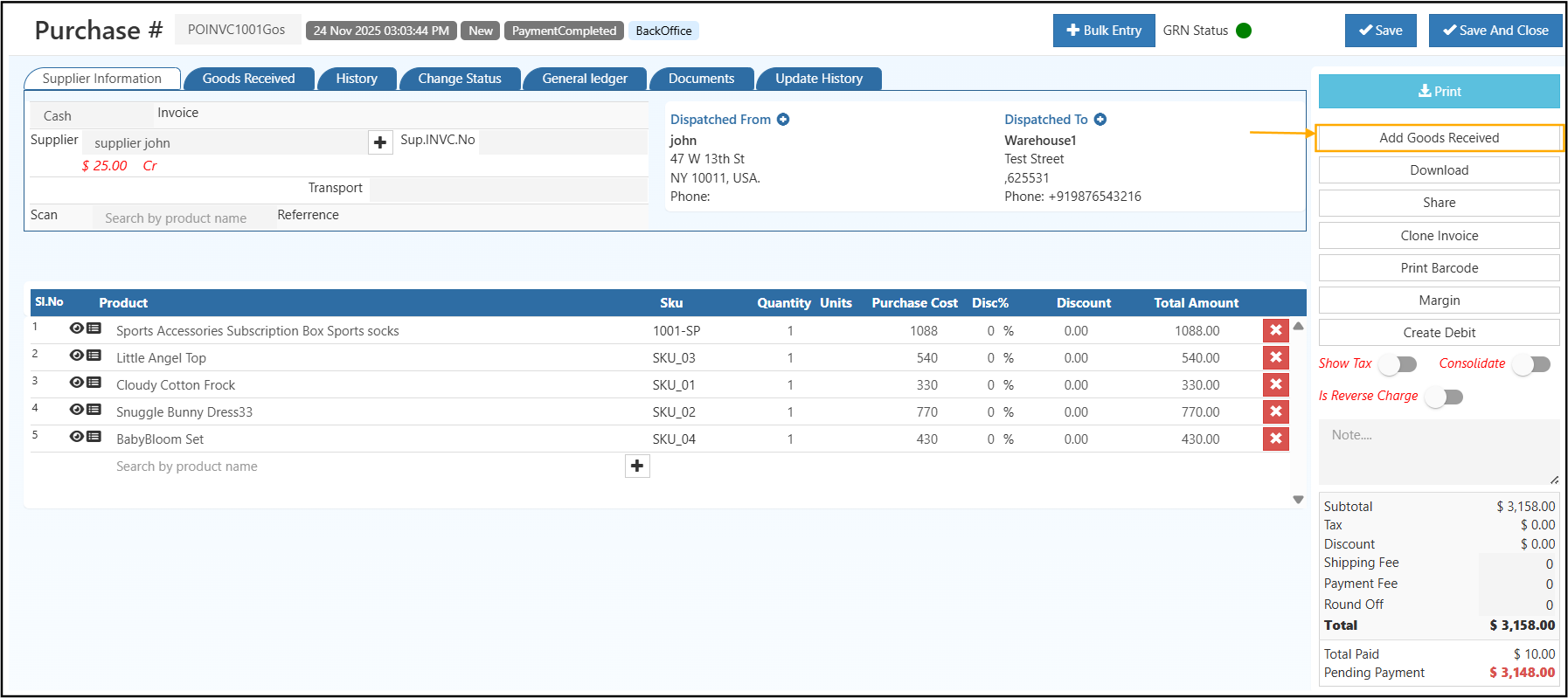

Location of the Goods Received (GRN) button in the Purchase Invoice Edit screen

Steps to Create GRN:

- Create or open a Purchase Invoice

- Click the Goods Received (GRN) button

- Enter received quantities and courier details

- Click Save to update inventory

ℹ️ Important: Inventory updates only after saving the GRN.

Creating a Purchase Invoice alone does not update stock.

How GRN Is Created in O2VEND

Although most users create GRN from the Purchase Invoice, O2VEND supports multiple goods receiving workflows.

GRN Creation Sources

- Purchase Invoice (Edit Page) – Standard supplier inward process

- Inventory → Incoming Packages – Receive stock before invoice generation

- Receipt Challan – Goods received first, invoice created later

- Debit Note – Replacement or supplier return scenarios

Why GRN Is Critical for Inventory Accuracy

GRN acts as the central stock inward control document in O2VEND.

It ensures:

- Accurate real-time stock updates

- Support for partial goods receipt

- Lot and serial traceability

- Clear approval-based inventory posting

- Alignment between warehouse and finance

Using GRN properly eliminates inventory discrepancies and ensures audit-ready stock management.

Table of Contents

- GRN Overview

- How to Create GRN in O2VEND

- GRN Top Actions

- GRN General Tab Fields

- GRN Product Table Fields

- Add Package Panel

- Packages Tab Workflow

GRN Overview

The Goods Receive (GRN) screen in O2VEND is the primary control point for stock inward verification.

It allows you to:

- Record courier and transport details

- Verify received product quantities

- Assign lot or serial numbers

- Update warehouse stock in real time

- Manage package dimensions for logistics

This structured process ensures accurate reconciliation between purchase invoices and physical stock—eliminating inventory mismatches.

How to Create GRN in O2VEND

Follow these simple steps to record goods received and update inventory correctly.

Step 1: Open GRN Screen

From the Purchase Invoice Edit Page, click the Goods Received (GRN) button.

Step 2: Verify Product Details

The system auto-fills:

- Product Name

- SKU

- UOM

- Ordered Quantity

Review all details before entering received quantities.

Step 3: Enter Courier Details

Add the shipment tracking number provided by the transporter.

Step 4: Select Receiving Location

Choose the correct warehouse or branch where stock will be stored.

Step 5: Enter Received Quantity

Input the actual quantity received.

- Partial receipt is allowed

- Quantity cannot exceed ordered quantity

Step 6: Save GRN

Click Save to:

- Validate entries

- Update inventory stock

- Change status to Goods Received

Inventory updates only after saving the GRN.

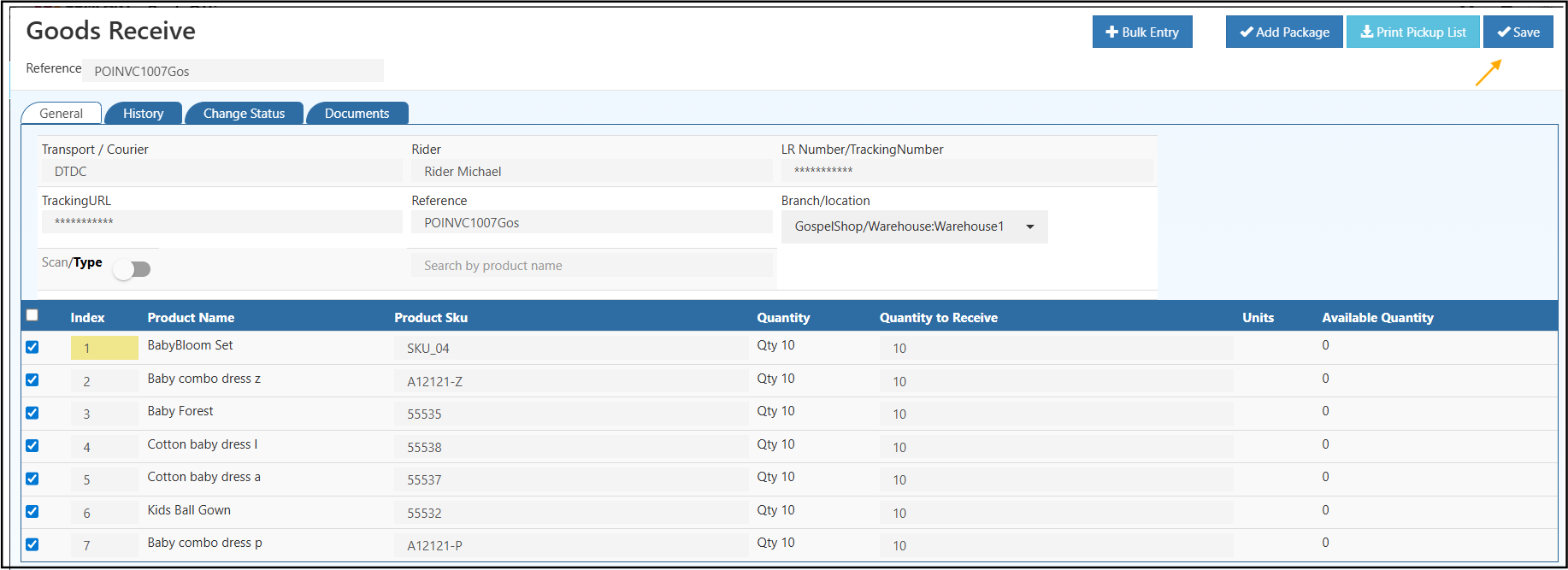

Goods Receive Note (GRN) creation screen from Purchase Invoice in O2VEND

Step 7: Add Lot / Serial Numbers (If Required)

Enter batch or serial numbers for products with tracking enabled.

Step 8: Print Receipt Challan

Generate a receipt copy for warehouse records or audit purposes.

Tip: Always review the History tab to verify successful stock update and workflow tracking.

GRN General Tab Fields

The General Tab captures transport, delivery, and receiving details.

Key Fields Explained

- Transport / Courier – Delivery partner name (e.g., Delhivery, BlueDart)

- Rider – Delivery person’s name

- LR / Tracking Number – Shipment tracking ID

- Tracking URL – Direct courier tracking link

- Reference – Internal purchase reference for cross-verification

- Branch / Location – Receiving warehouse location

- Scan / Type Mode – Enables barcode scanning for faster entry

- Receiving Address – Complete delivery address and contact information

Accurate entry in this tab ensures shipment traceability and smooth audit verification.

GRN Top Actions

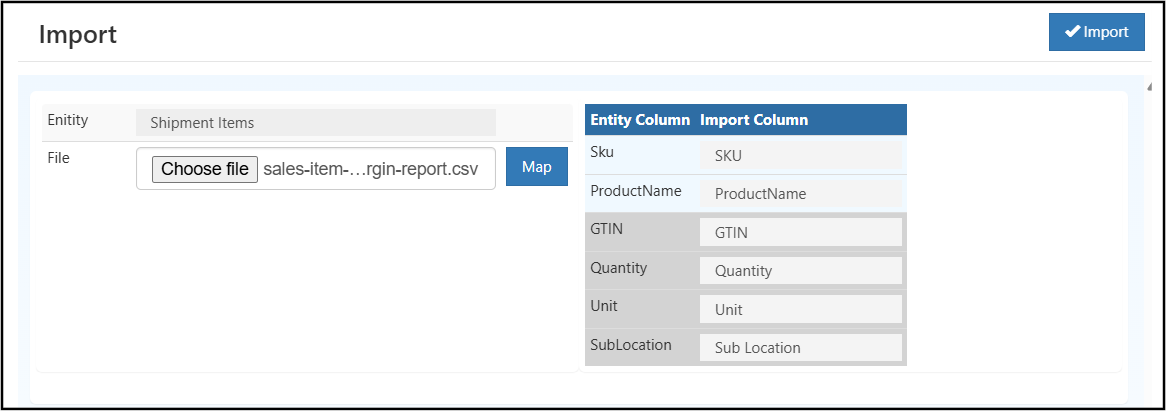

Bulk Import (High-Volume Entry)

Use Bulk Import when receiving large quantities of products.

Bulk Import feature in Goods Receive (GRN) for mass stock inward entry – O2VEND

Bulk Import feature in Goods Receive (GRN) for mass stock inward entry – O2VEND

How Bulk Import Works:

- Open GRN under Purchase

- Click Bulk Import

- Upload Excel file

- Map spreadsheet columns

- Confirm and import data

This method significantly reduces manual entry errors and speeds up warehouse processing.

Bulk Import Column Mapping

| Entity Column | Import Column | Description |

|---|---|---|

| SKU | Sku | Unique product identifier |

| GTIN | Gtin | Global Trade Item Number / Barcode |

| Product Name | Name | Product description |

| Quantity | Quantity | Units received |

| Unit | Units | UOM (PCS, BOX, KG) |

| SubLocation | Sub Location | Bin / Rack allocation |

Ensure spreadsheet headers exactly match system expectations for successful import.

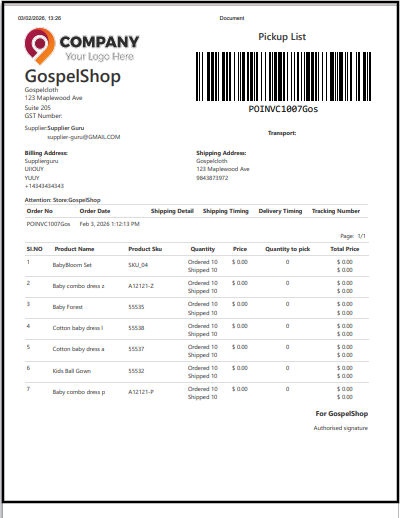

Print Pickup List

The Print Pickup List generates a consolidated summary of all items included in the GRN.

Print Pickup List feature in Goods Receive (GRN) for warehouse verification – O2VEND

This report helps warehouse teams to:

- Verify received quantities

- Cross-check SKUs physically

- Confirm package contents

- Maintain documentation for audits

Use this option before final approval to ensure accurate stock inward verification.

Save & Finalize GRN

Clicking Save completes the GRN process.

When saved:

- Inventory stock is updated instantly

- Product quantities are validated

- GRN status changes accordingly

- Linked Purchase Invoice remains synchronized

Important: Stock levels will not update until the GRN is saved and approved.

This step ensures financial records and physical inventory remain aligned.

Reference Field in GRN

The Reference field displays the internal purchase reference number linked to the transaction.

It is used for:

- Purchase Order verification

- Cross-department tracking

- Audit validation

- Internal reconciliation

Accurate referencing improves traceability across procurement and inventory modules.

GRN Tabs Overview

O2VEND organizes GRN information into structured tabs for better workflow control.

1. General Tab

Primary data entry section for:

- Courier details

- Receiving location

- Product list

- Scan mode

2. History Tab

Maintains a chronological audit log including:

- GRN creation

- Edits

- Status changes

- Approval actions

This ensures complete transparency for internal audits.

3. Change Status Tab

Used to manually update the GRN workflow stage based on shipment progress.

4. Documents Tab

Stores supporting files such as:

- Supplier invoices

- Delivery challans

- Packaging lists

- Shipment labels

Centralized document storage simplifies compliance management.

GRN Status List Explained

The Change Status tab helps track shipment lifecycle.

| Status | Meaning |

|---|---|

| InTransit | Shipment is en route |

| OutForDelivery | Assigned for final delivery |

| Delivered | Arrived at location, pending verification |

| InProcess | Receiving activity ongoing |

| GoodsUnderInspection | Under quality verification |

| Accepted | Goods verified and approved |

| GoodsReceived | Stock updated in inventory |

| GoodsReturned | Items returned to supplier |

| ReStocked | Returned items added back to stock |

| AttemptFail | Delivery attempt failed |

| Exception | Shipment issue (damage, delay, mismatch) |

| PickedUp | Returned items collected |

| Unknown | Status not detected |

Clear status tracking prevents stock confusion and improves operational visibility.

GRN Product Table Fields

The Product Table captures item-level receiving details.

| Field | Description |

|---|---|

| Product Name | Name of received item |

| Product SKU | Unique stock identifier |

| Quantity | Ordered or supplier-confirmed quantity |

| Sub Location | Warehouse bin/rack allocation |

| Quantity to Receive | Editable received quantity (partial receipt supported) |

| Units | Unit of measurement (PCS, KG, BOX, Each) |

| Lot Number | Batch identifier for traceability |

| Expiry Date | Use-by date (supports FEFO management) |

| Allot Lot | Create or assign lot for inventory tracking |

Accurate product entry ensures real-time stock accuracy and prevents over-receiving errors.

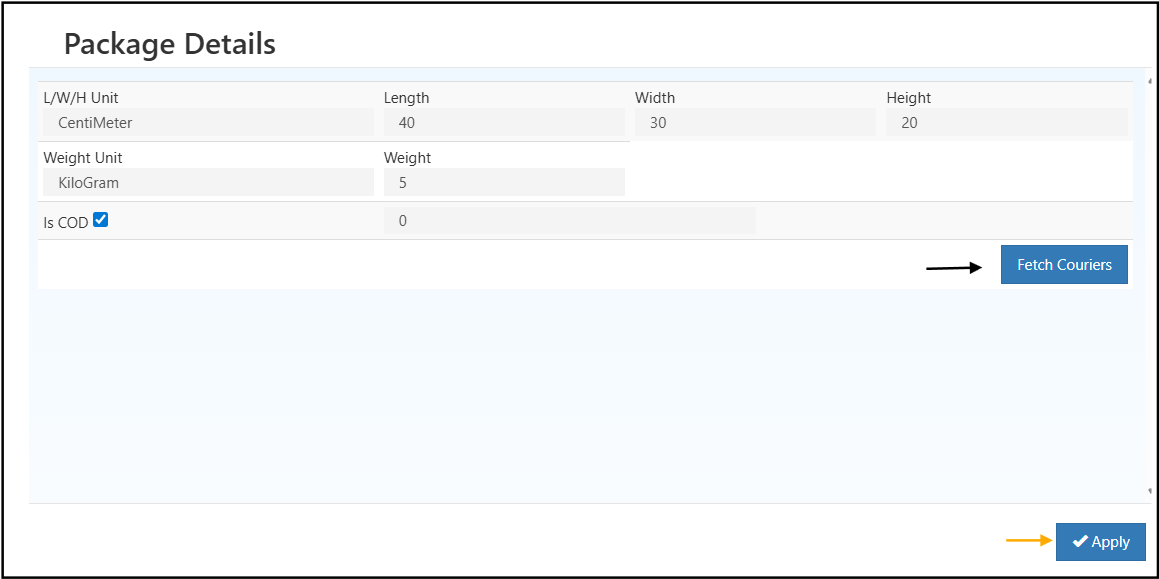

Add Package Panel (GRN Package Details)

The Add Package option captures parcel dimensions and weight during goods inward.

This is especially useful when integrating with courier or logistics systems.

Example of Package Details entered in Goods Receive Note (GRN) – O2VEND

Package Fields Explained

- L/W/H Unit – Dimension unit (Inch or Centimeter)

- Length – Longest side of the package

- Width – Side measurement perpendicular to length

- Height – Vertical dimension

- Weight Unit – Gram or Kilogram

- Weight – Actual package weight

- Is COD – Indicates Cash on Delivery eligibility

- Fetch Couriers – Retrieves available courier partners

- Apply – Saves package configuration

Capturing accurate package details ensures smoother logistics handling and correct shipment processing.

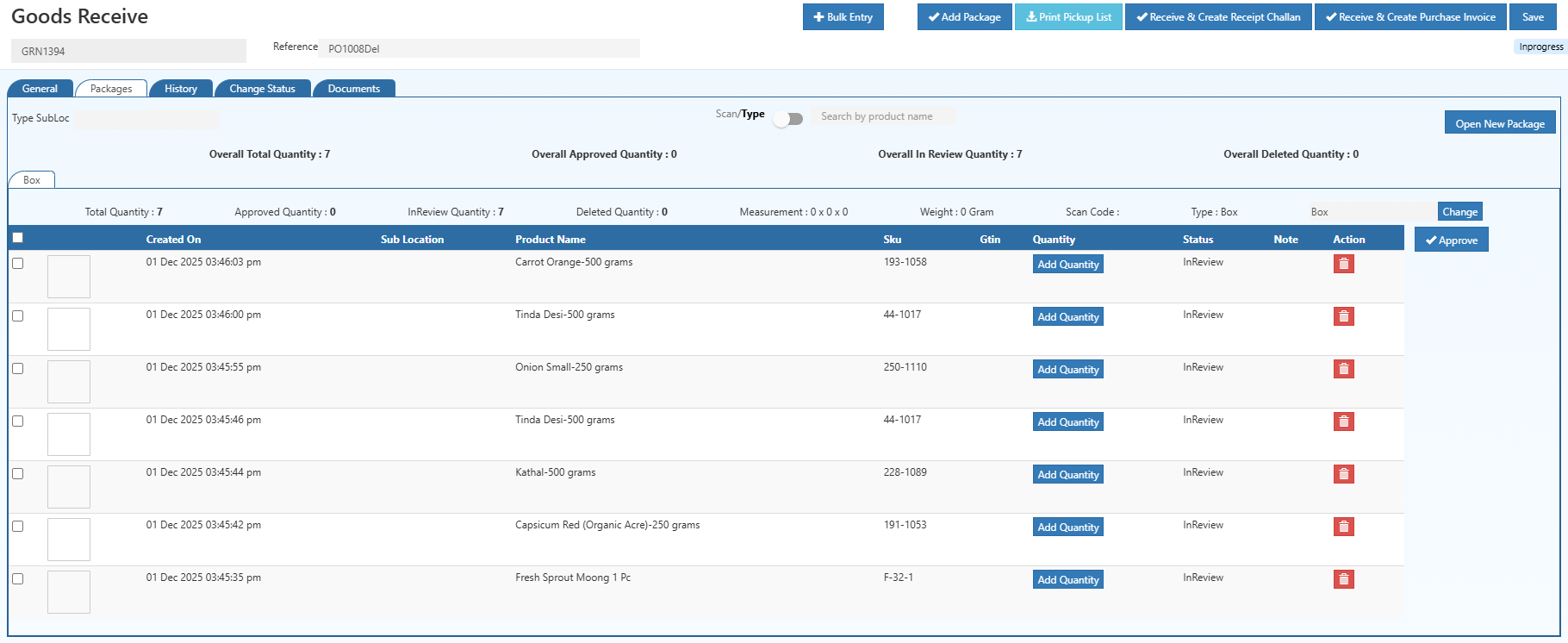

Packages Tab – Managing Goods Receive (GRN) in O2VEND

Once the Goods Receive (GRN) process is initiated, the Packages Tab becomes the main control center for package-level stock management.

Here you can:

- Organize received products into packages

- Verify items at product level

- Approve before inventory posting

- Allocate stock to warehouse sub-locations

Using this tab ensures accurate inventory and prevents stock mismatches.

Packages Tab in Goods Receive (GRN) showing package-level stock verification and approval – O2VEND

Step-by-Step Package Management

1. Packages Tab Overview

The tab shows a clear summary of all GRN packages:

- Sub-location per package

- Total product quantity

- Status: Approved, In-Review, Deleted

Provides visibility for warehouse teams before final approval.

2. Create a New Package

For multiple cartons or pallets, create separate packages to:

- Organize stock

- Allocate storage accurately

- Track items for audits

3. Select Package Material

Choose from:

- Small / Medium / Large Box

- Pallet

O2VEND auto-applies dimensions, weight, and labels for consistent handling.

4. Add Products to Package

Add items via:

Barcode scan (fast + accurate)

Manual entry

Status defaults to In-Review

⚠️ Only Approved quantities update inventory.

5. Approve or Reject Products

Review each product:

- Approve items in good condition

- Reject damaged, incorrect, or excess items

Ensures inventory accuracy and quality control.

6. Save and Finalize GRN

After verification:

- Save package entries

- Click Approve

- Stock updates automatically

- Only verified items reflect in inventory

- GRN status changes to Approved

Why the Packages Tab Matters

Proper use of this tab helps:

- Validate every received item

- Maintain traceability

- Reduce stock entry errors

- Improve audit compliance

- Strengthen warehouse control

The package workflow adds a verification layer, making O2VEND’s GRN process reliable and secure.