Inventory Stock Quantity in O2VEND ERP | Stock Control

Track, adjust, and control inventory stock quantity in O2VEND ERP with audit-ready stock tracking. Stock mismatches, incorrect orderable quantities, and missing lot or expiry details often result in fulfillment delays, audit issues, and inventory losses.

The Inventory Stock Quantity module in O2VEND ERP enables structured inventory control, reliable stock tracking, and controlled stock adjustments across warehouses and sub-locations.

This section explains how to view inventory stock quantity, apply manual stock adjustments, track orderable stock movement, and maintain lot, batch, manufacturing date, and expiry records for audit-ready inventory operations.

This module supports warehouse teams, inventory controllers, and audit operations.

📊 Accurate stock quantity directly impacts order fulfillment, revenue, and audit compliance.

This module prevents overselling, expired stock issues, and reconciliation errors.

What This Module Delivers

- Real-time inventory stock quantity visibility

- Accurate stock adjustments with full audit trail

- Lot, batch, manufacturing, and expiry tracking

- Audit-ready warehouse inventory control

Accessing Stock Quantity

Navigation Path

Back Office → Inventory → Stock Quantity

This screen lists all products mapped to the selected warehouse along with real-time stock information.

🔔 Important

Only products added to a warehouse appear in this section.

Refer to Manage Warehouse to create location.

Search, Filters, and Export Options in Stock Quantity

The Stock Quantity screen provides inline search filters and an Advanced Filters panel to narrow down inventory records and perform accurate stock analysis.

Export Stock Quantity Data

The Stock Quantity screen allows inventory data export for review and reporting.

Export Current Page

Downloads only the products visible on the current screen, based on applied filters.

Useful for quick checks and small data reviews.

Export All

Downloads the complete stock quantity list across all pages, respecting active filters.

Ideal for full inventory audits and reporting.

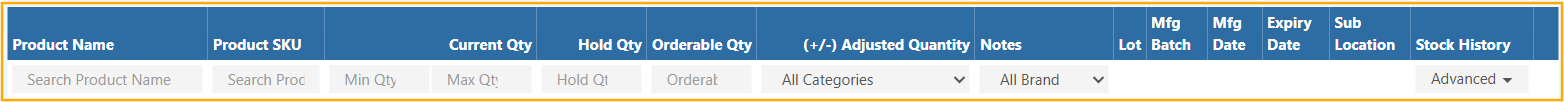

Inline Search Filters

Filters and Search in Stock Quantity

Inline search fields appear directly below the column headers and allow quick filtering within the stock list.

Available inline filters:

- Product Name – Search using product display name

- Product SKU – Filter by SKU or internal product code

- Current Qty (Min / Max) – Identify low or excess stock

- Hold Qty – View products with reserved stock

- Orderable Qty – Filter by sellable stock availability

These filters help quickly locate products with stock variance or availability issues.

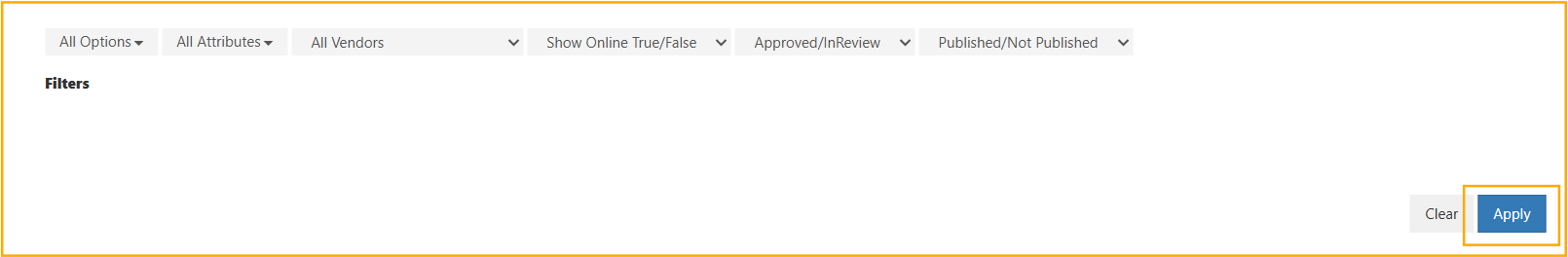

Advanced Filters

Selecting Advanced opens the complete filter panel.

All dropdown-based filters are available only inside this section.

Filters available inside Advanced Filters:

- Options – Filter products based on configured options

- Attributes – Narrow inventory using product attributes

- Vendors – View stock linked to specific vendors

- Show Online (True / False) – Filter products available for online sale

- Approval Status (Approved / In Review) – Review product approval state

- Publish Status (Published / Not Published) – Identify catalog visibility

Advanced filters support deep inventory review, catalog validation, and audit-ready stock analysis.

✅ Apply and Clear Actions

- Apply – Displays stock quantity data based on selected filter conditions

- Clear – Resets all filters and restores the default inventory view

These actions help maintain controlled filtering without affecting inventory data.

Information Displayed

Each row represents a product with detailed inventory data:

- Product Name & SKU – Product identification

- Current Quantity – Physical stock available

- Hold Quantity – Reserved stock

- Orderable Quantity – Available stock for orders

- Adjusted Quantity (+ / -) – Manual stock correction

- Lot / Batch / Expiry – Lot-level inventory control

- Notes – Reason for stock change

- Actions – Create Lot, View Lots, sublocation details, View History

This consolidated view supports accurate inventory control and reliable stock tracking.

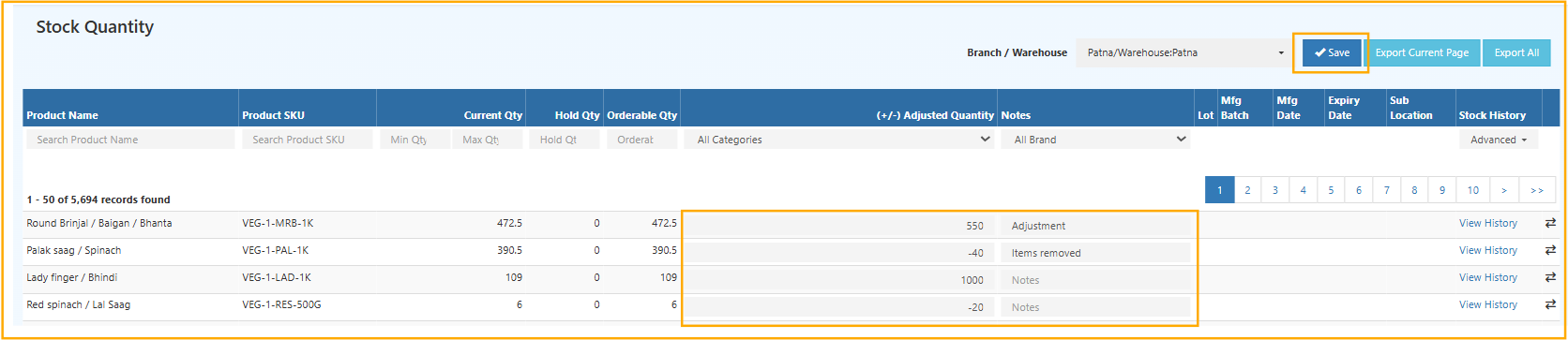

Updating Inventory Stock Quantity

When Stock Adjustment Is Required

Stock adjustments are typically performed during:

- Physical stock audits

- Damage or loss reporting

- Initial stock entry

- Manual corrections during reconciliation

Steps to Adjust Stock Quantity

Step 1: Select Warehouse / Location

Choose the required Branch / Warehouse from the dropdown list.

✅ Ensures stock changes apply to the correct location

Step 2: Enter Adjusted Quantity

Enter values in the Adjusted Quantity column:

- Positive value to increase stock

- Negative value to reduce stock

Examples:

+10→ Adds stock-2→ Removes stock

This update recalculates current and orderable stock levels.

Step 3: Add Notes

Provide a clear reason in the Notes field.

Recommended examples:

Stock take adjustment – Jan auditDamaged items removedPO#987 – manual inward

✍️ Notes help maintain a clear audit trail for inventory changes.

Step 4: Save the Adjustment

Click Save to apply changes.

- Current Quantity updates immediately

- Orderable Quantity recalculates automatically

- Stock history is recorded for future reference

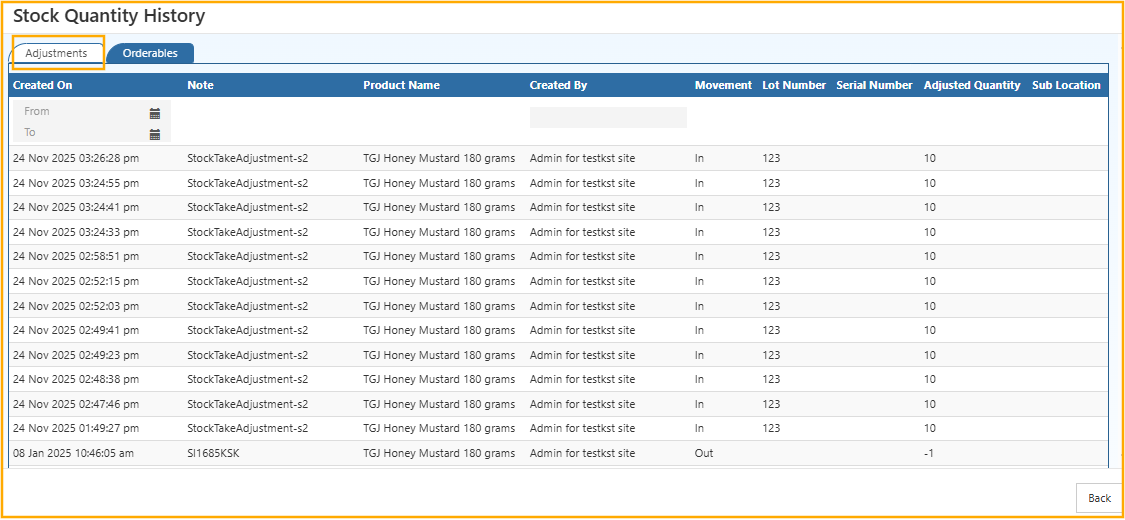

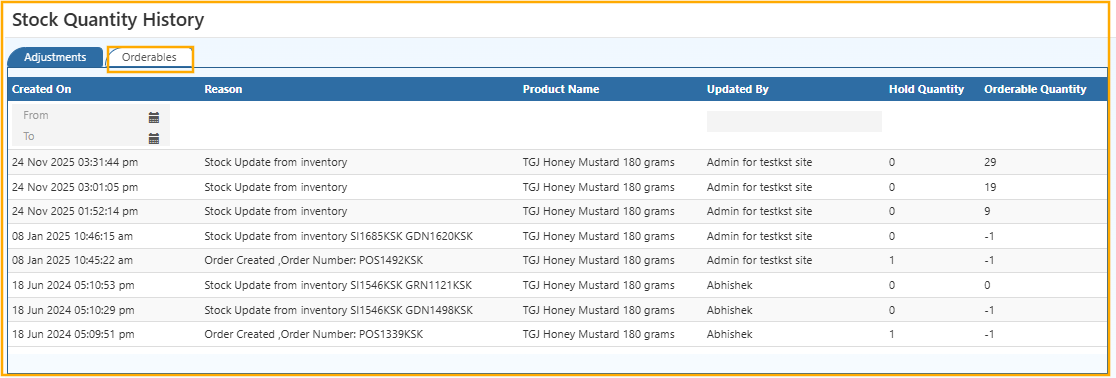

Stock History Tabs – Inventory Movement Breakdown

The Stock History section is divided into two purpose-driven tabs.

Each tab highlights a different type of inventory movement to ensure clear accountability, traceability, and inventory accuracy.

How to View History

Select the required product row and click View History to view all stock movements recorded for the item.

This section maintains a complete, audit-ready timeline of inventory changes for accuracy and traceability.

Adjustments Tab

The Adjustments tab displays all manual stock corrections, including the adjustment date, reason, quantity change, lot reference, sub-location, and the user who performed the update.

This view helps validate inventory corrections made during audits, damage reporting, or reconciliation activities.

Orderables Tab

The Orderables tab shows stock movements generated by sales orders and stock reservations, reflecting how available inventory is consumed through order processing.

This view explains changes in orderable quantity over time and supports accurate sales availability tracking.

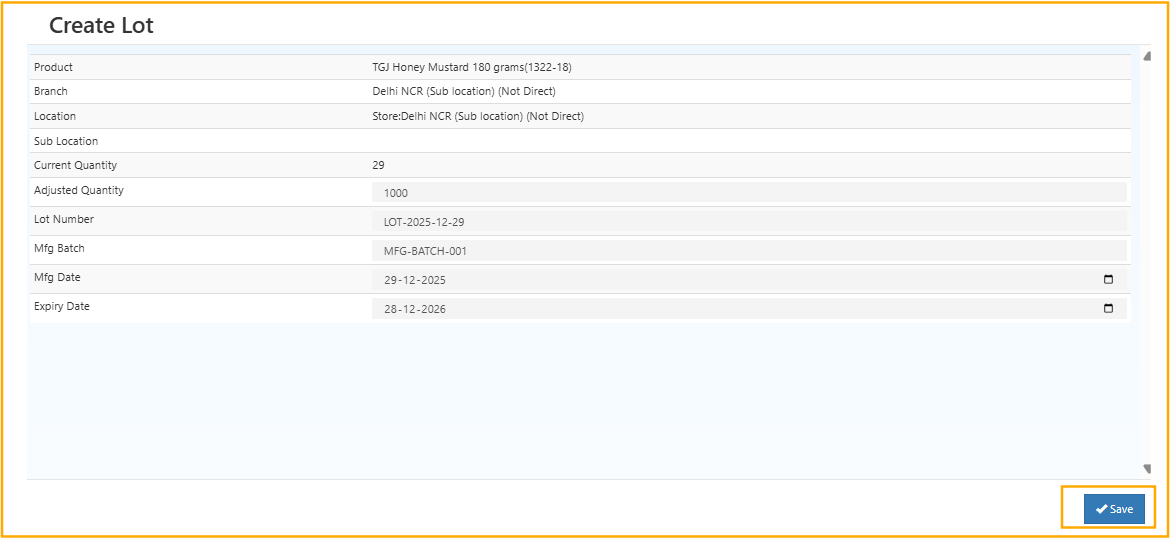

Managing Lot-Based Inventory

Lot tracking is essential for products requiring batch control, expiry monitoring, or regulatory compliance.

Creating a Lot

Select Create Lot for lot-enabled products.

Lot Field Definitions

| Field | Example | Description |

|---|---|---|

| Lot Number | LOT-2025-12-29 | Unique batch identifier |

| Adjusted Quantity | 1000 | Quantity assigned to the lot |

| Mfg Batch | MFG-BATCH-001 | Manufacturing batch reference |

| Mfg Date | 29-12-2025 | Production date |

| Expiry Date | 28-12-2026 | Product expiry date |

📌 Date format: DD-MM-YYYY

Click Save to create the lot.

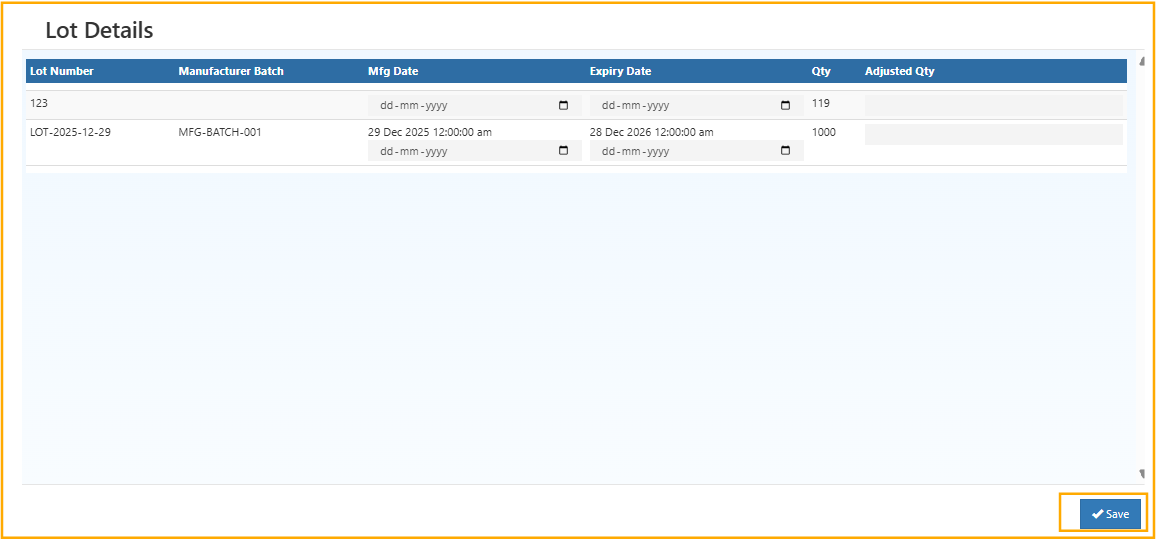

Viewing Lot Details

Select View Lots to access:

- Lot numbers

- Manufacturing batch information

- Manufacturing and expiry dates

- Lot-wise quantities

- Adjusted quantities

This supports FIFO / FEFO, expiry management, and recall tracking.

This supports FIFO / FEFO, expiry management, and recall tracking.

Sub Location Stock Transfer

The Sub Location Transfer screen opens when the stock transfer icon is selected from the Stock Quantity list.

This feature is used to move stock between sub-locations within the same warehouse without changing the total inventory quantity.

Screen Details

- Product – Displays the selected product name and code

- Branch – Shows the branch where stock is maintained

- Location – Main warehouse linked to the product

- From Sub Location – Source sub-location of the stock

- Current Quantity – Available stock in the source sub-location

Transfer Information

- To Sub Location – Destination sub-location inside the warehouse

- Quantity – Stock quantity to be moved

- Remove (✖) – Deletes the destination row if not required

This process ensures accurate sub-location-level inventory control and smooth warehouse operations.

Related Topics

- Create Delivery Challans from Inventory

- View Complete Stock History Reports

- Warehouse to Warehouse Stock Transfer

🔗 Learn More from O2VEND Blogs

For detailed strategies, tips, and step-by-step guidance, check out these O2VEND blogs:

- Innovative Inventory Strategies: Preventing Stockouts & Overstock

- Reduce Stockouts & Overstocks with Simple Forecasting

- Simplify Your Inventory Management with O2VEND Back Office

- 5 Tips for Improving Your Inventory Management with O2VEND

- How to Do Physical Inventory / Stock Taking Processes in O2VEND