Inventory Stock History – Track Stock Movement & Audit Trail

Track complete inventory stock history including stock in, stock out, lot, serial, and warehouse movement logs. This module provides a full audit trail to ensure accurate inventory control and warehouse accountability.

This guide explains how to manage Stock History inside the O2VEND Inventory Module.

Stock History provides a complete inventory audit trail, helping track stock movements, lot and serial details, SKU-level activity, warehouse actions, adjustments, and reference-based changes.

It helps maintain accurate inventory, prevents stock mismatches, and ensures smooth warehouse operations.

What Is Inventory Stock History?

Stock History is a chronological record of all inventory activities across purchases, sales, transfers, manufacturing, and stock adjustments.

It provides a complete view of stock movement at SKU level, supporting audits, operational analysis, and accurate inventory tracking.

Businesses use the Stock History report to monitor:

- Inventory movement and transaction logs

- SKU-level tracking and traceability

- Warehouse stock records

- Lot and serial number movements

- Stock in and stock out history

- Inventory audit trail and adjustments

- Quantity changes and corrections

- Inward and outward stock flow

- Reference-based actions (GRN, GDN, transfers, vouchers)

- Stock movement across branches and warehouses

This report acts as a centralized inventory movement tracking system, offering clear visibility into how products move within the organization and who performed each action.

It is widely used by warehouse managers, auditors, and operations teams to ensure stock accuracy, compliance, and reliable inventory control.

How to View Inventory Stock History

- Open the Back Office

- Go to Inventory

- Click Stock History

- View complete movement logs for all SKUs

- Use filters to refine by:

- Date range

- SKU

- Product

- Lot number

- Serial number

- Location

This section displays the entire Warehouse Stock Log for better audit clarity.

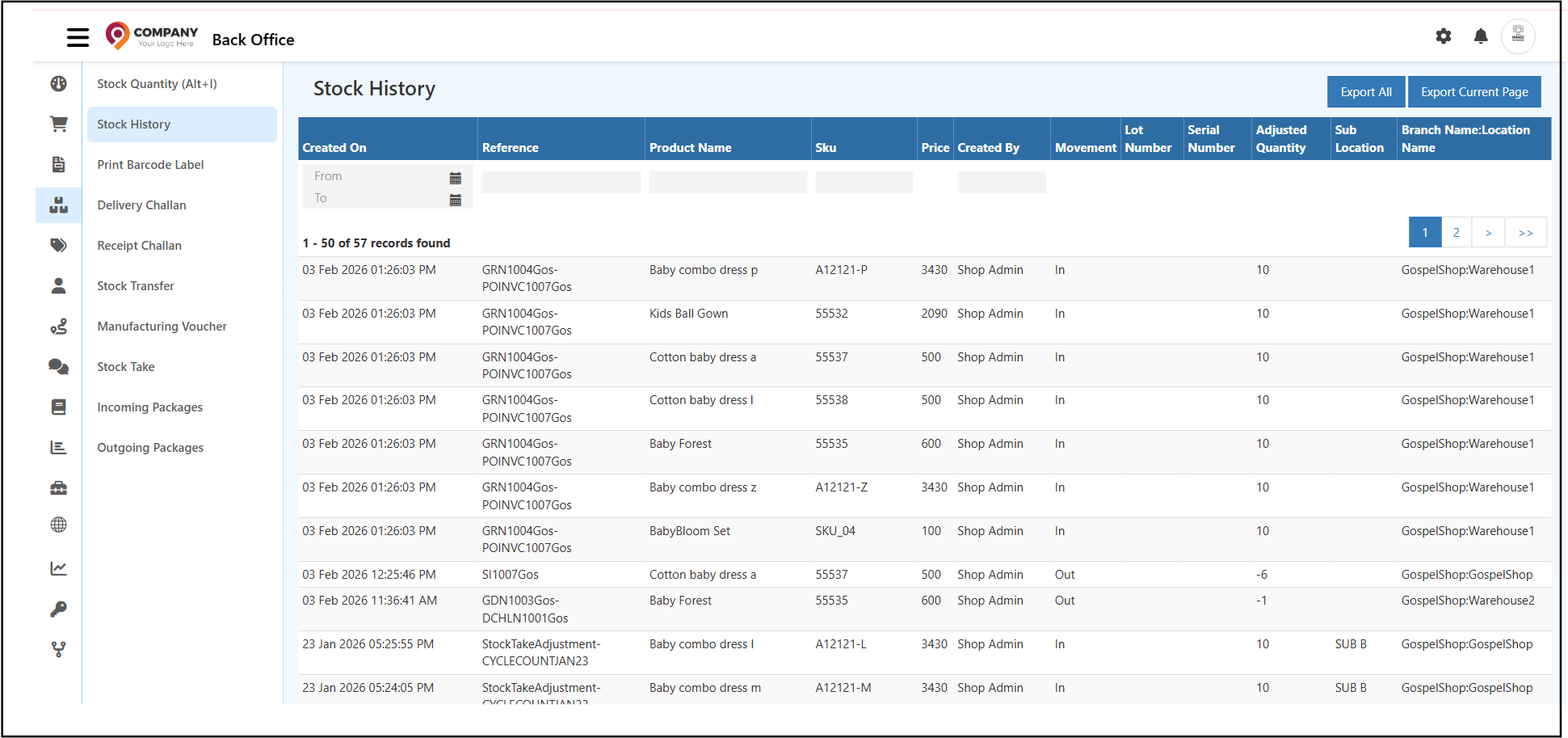

Inventory Stock History screen displaying stock in and stock out movements with SKU, lot, serial, and warehouse location details.

Inventory Stock History Fields Explained

Created On

Shows the date and time when the stock movement was recorded.

Reference

Indicates the source of the movement such as:

- Sales order

- Purchase entry

- Return

- Adjustment

- Transfer

Each reference helps identify the reason behind inventory change.

Product Name

Displays the product involved in the movement.

Use product search to filter specific items.

SKU

The SKU Tracking feature allows you to identify individual product records.

Search by SKU to view item-specific history.

Price

Displays the price of the item involved in that specific movement.

Created By

Name of the admin or employee who performed the action.

Useful for tracking responsibilities.

Movement (IN / OUT)

Stock movements are classified into two types:

- IN – Stock added to inventory

- OUT – Stock removed from inventory

These movements help monitor:

- Incoming purchase stock

- Sales deductions

- Adjustments

- Warehouse transfers

This ensures accurate Stock In and Stock Out History and supports better forecasting.

Lot Number Tracking in Inventory Stock History

Lot Number Tracking allows batch-wise monitoring of products.

Useful for items with:

- Expiry dates

- Manufacturing batches

- Safety-sensitive products

It provides complete traceability of each batch as part of the Inventory Audit Trail.

Serial Number Tracking for Inventory Items

A Serial Number is a unique identifier assigned to individual units.

This feature helps track:

- High-value items

- Warranty details

- Repairs & replacements

- Product ownership history

Using Serial Number Movement, users can trace every action performed on a specific item from purchase to sale.

Adjusted Quantity and Stock Corrections

Shows quantity manually adjusted from:

- Product page

- Stock inventory

- Admin stock correction

This ensures full transparency in the Inventory Audit Trail.

Sub Location

Warehouse sub-bin or rack location.

Branch Name / Location Name

Indicates the branch and warehouse where the movement occurred.

Shows the exact warehouse or store location where the stock was added or removed.

Important for multi-warehouse operations and accurate Warehouse Stock Log maintenance.

Filters and Search Options in Stock History

The Stock History page supports filters to quickly analyse movements:

- From / To Date - for period-based tracking

- Reference filter - to identify specific GRN, GDN, MV, etc.

- Product name filter - for product-level movement study

- SKU filter - for precise SKU traceability

- Created By - to analyse entries created by specific staff

These filters optimise inventory audits and reconciliation tasks.

Export Inventory Stock History Reports

The Stock History module includes export actions:

- Export Current Page - Downloads only the visible records

- Export All - Downloads complete stock movement history

Useful for offline audit, MIS reporting, or compliance verification.

When to Use Stock History

Use the Stock History report when you need to:

- Investigate stock mismatches or quantity issues

- Audit warehouse transactions

- Track stock movement for compliance or reporting

- Verify lot or serial-based product flow

- Reconcile inventory during stock take or adjustments

Key Benefits of Inventory Stock History

- Accurate end-to-end inventory visibility

- Fast identification of incorrect or duplicate entries

- Strong support for warehouse audit trails

- Better control over lot/serial-based tracking

- Complete traceability of stock from purchase to sale

- Enhanced accuracy in inventory valuation and reconciliation

--