Stock Transfer in O2VEND – Complete Branch Inventory Movement & Goods Workflow Guide

Complete guide to Stock Transfer in O2VEND inventory system. Learn branch-to-branch stock movement, goods issue, goods receive, workflow control, and real-time inventory updates.

Stock Transfer in O2VEND is a structured inventory control process designed to manage product movement between branches, warehouses, retail outlets, and storage locations.

The system ensures:

- Real-time stock synchronization

- Transparent movement tracking

- Accurate financial reflection

- Branch-level inventory visibility

- Complete operational control

For businesses operating multiple locations, controlled stock transfer is essential to prevent stock shortages, overstocking, and inventory discrepancies.

Understanding Stock Transfer in O2VEND

Stock Transfer refers to internal inventory movement within the same organization. Unlike purchase or sales transactions, stock transfer does not affect external vendors or customers but impacts internal stock balances between branches.

O2VEND’s Stock Transfer module provides:

- Automatic stock history recording

- Status-based inventory updates

- Branch-wise quantity control

- Audit-ready movement logs

- Integrated financial tracking (if configured)

This structured process eliminates manual errors and ensures consistent inventory data across all locations.

Business Scenarios Where Stock Transfer is Required

Stock Transfer is commonly used in the following situations:

- Moving goods from central warehouse to retail stores

- Redistributing stock between high-demand and low-demand branches

- Emergency stock replenishment

- Seasonal inventory allocation

- Transferring excess stock to reduce dead inventory

- Internal returns from store to warehouse

A centralized stock movement system improves operational coordination and ensures business continuity.

Step-by-Step Process to Create Stock Transfer in O2VEND

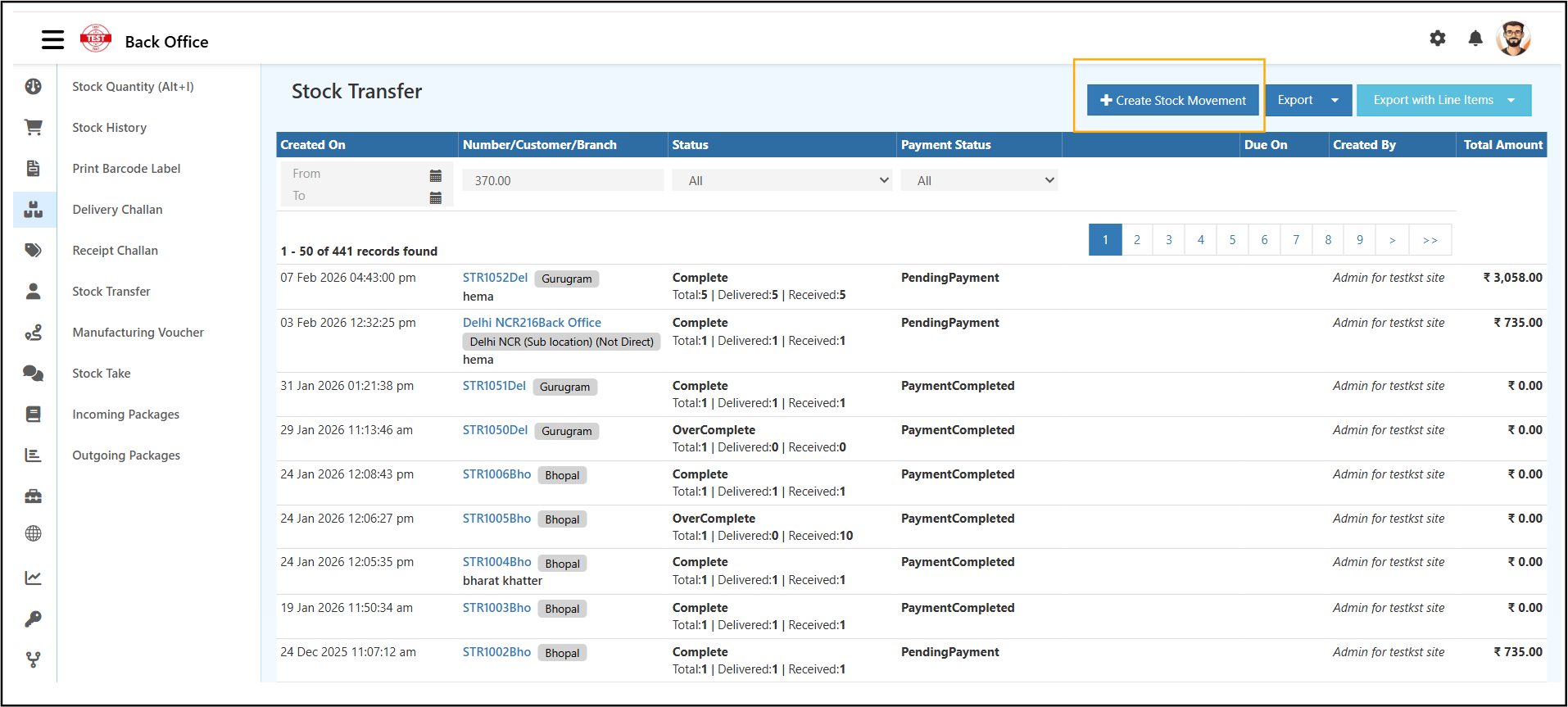

Step 1: Access Stock Transfer Module

- Go to Back Office

- Navigate to Inventory

- Click Stock Transfer

- Click + Create Stock Movement

Stock Transfer listing page with “Create Stock Movement” option in O2VEND Back Office.

This screen displays previous stock transfer records along with status and financial details.

Step 2: Select Branch and Location Details

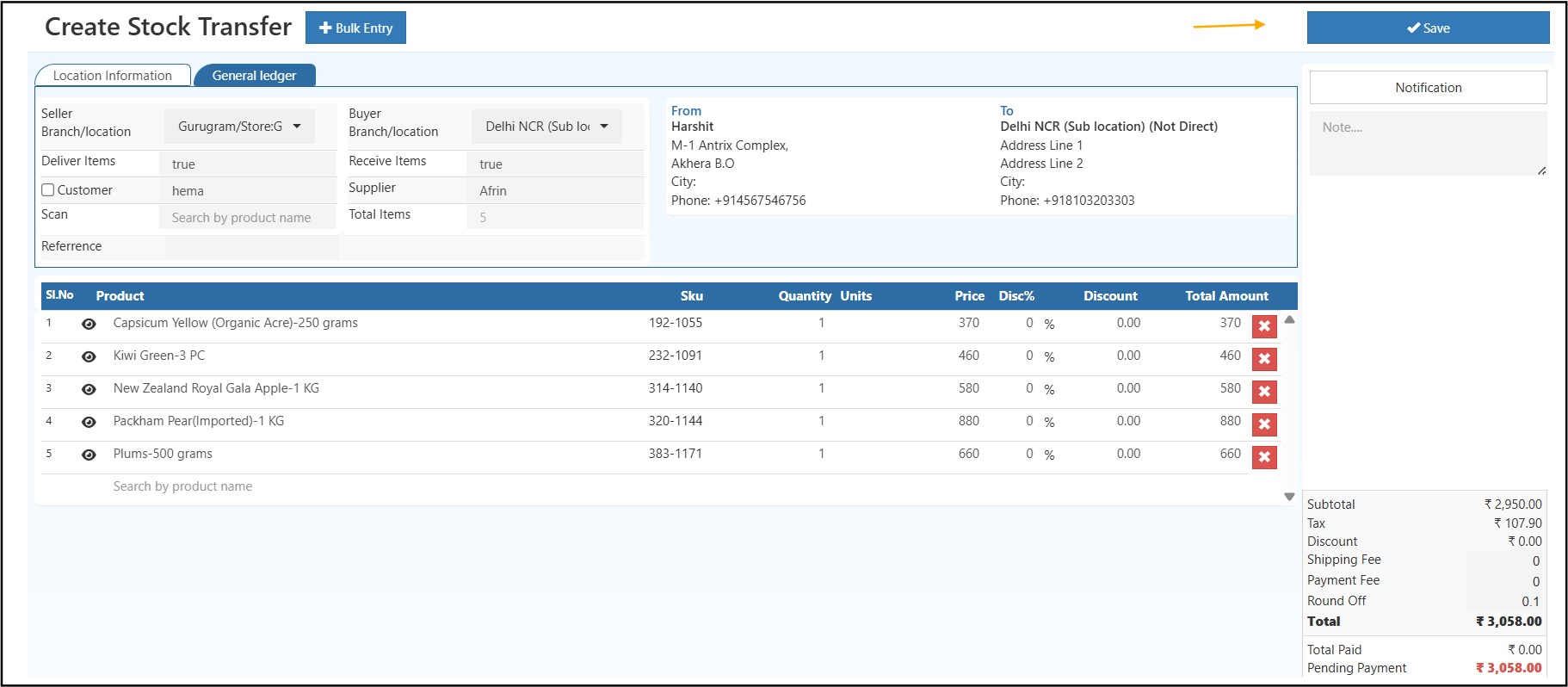

Stock Transfer creation page showing branch selection, product entry table, and summary section.

Select:

- Seller Branch (From Location) – Source branch

- Buyer Branch (To Location) – Destination branch

Once selected, the system automatically fills:

- Billing Address

- Shipping Address

- Branch Contact Information

Optional documentation fields include:

- Customer Name

- Supplier Name

- Reference Number

- Remarks

Proper branch selection is critical for accurate inventory adjustment.

Step 3: Add Products to the Transfer

Products can be added using the search field.

For each product, enter:

- Quantity

- Unit

- Price

- Discount (if applicable)

The system automatically calculates:

- Line Total

- Subtotal

- Tax

- Shipping Charges

- Round Off

- Grand Total

- Pending Payment

Multiple products can be included in a single transfer document, allowing bulk inventory movement between branches.

Verification of product quantity before saving ensures inventory consistency.

Step 4: Review Financial Summary

The summary section provides a clear breakdown of:

- Subtotal

- Tax Amount

- Discount

- Shipping Fee

- Total Amount

- Paid Amount

- Pending Payment

This ensures accounting accuracy and prevents financial mismatches between branches.

Step 5: Save the Stock Transfer Entry

Click Save or press Ctrl + S.

After saving:

- Transfer entry is recorded in stock history

- Status is updated as Pending or Complete (based on workflow)

- Financial synchronization occurs (if configured)

- Entry becomes available for Goods Issue and Goods Receive

Stock is not fully transferred until Goods Issue and Goods Receive are completed.

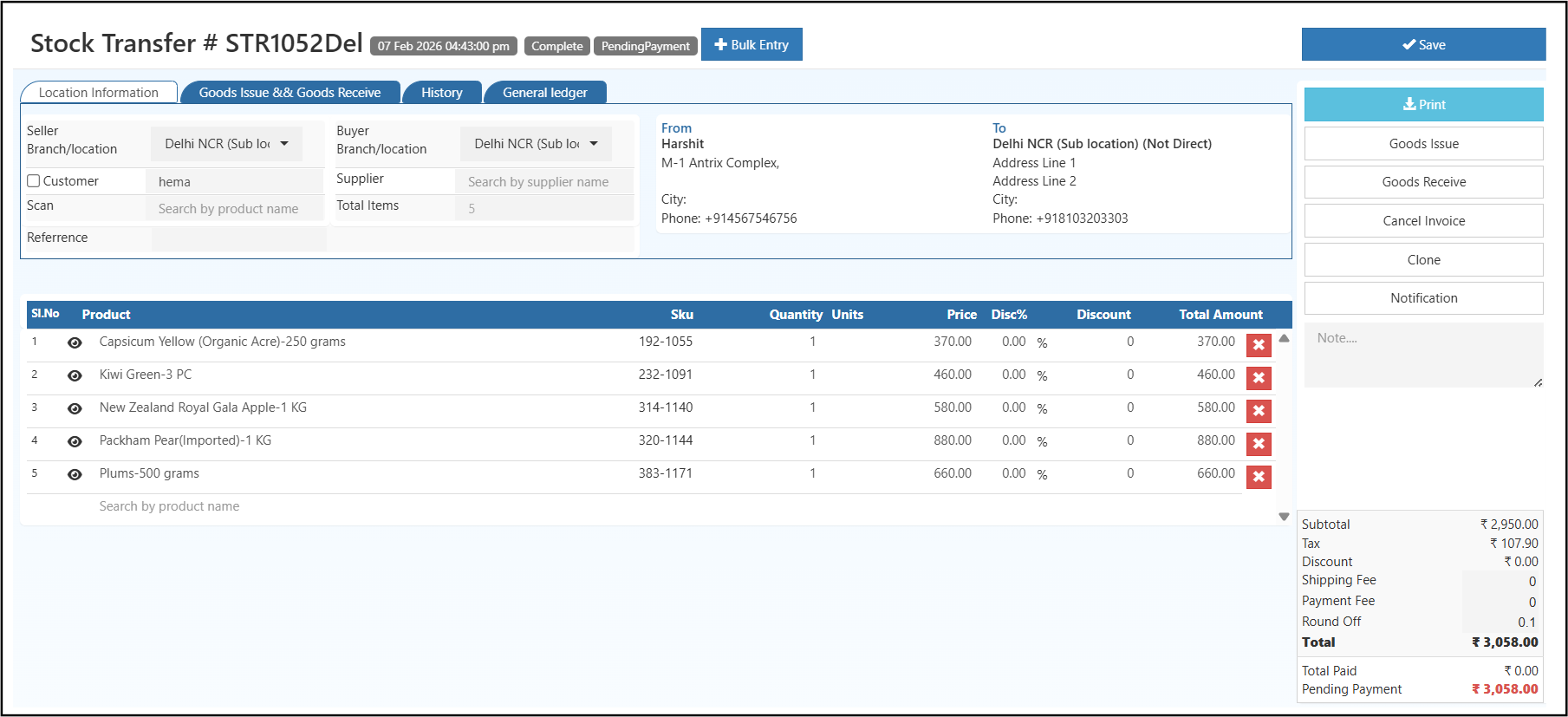

Goods Issue – Dispatch Confirmation from Source Branch

Goods Issue confirms that inventory has been dispatched from the source location.

Process:

- Open the saved Stock Transfer entry

- Click Goods Issue

- Enter dispatch quantity

- Click Save

- Print challan if required

After Goods Issue:

- Source branch stock is reduced

- Dispatch status is updated

- Movement history is recorded

This step ensures that inventory physically leaving the source branch is properly documented.

Goods Receive – Confirmation at Destination Branch

Goods Receive confirms that stock has arrived at the destination branch.

Process:

- Open the transfer entry

- Click Goods Receive

- Enter received quantity

- Click Save

- Print challan if required

After Goods Receive:

- Destination branch stock increases

- Transfer status becomes Complete

- Inventory ledger is updated

This final step ensures accurate stock reflection at the receiving branch.

Stock Transfer edit screen displaying Goods Issue, Goods Receive options and inventory summary.

Complete Stock Transfer Workflow Overview

- Create Stock Movement

- Add Products

- Save Entry

- Perform Goods Issue

- Perform Goods Receive

- Inventory Updates Automatically

This structured workflow ensures full transparency in branch inventory movement.

Inventory Control Advantages of Stock Transfer

Using O2VEND Stock Transfer provides:

- Real-time inventory synchronization

- Accurate branch-wise stock tracking

- Reduced manual inventory errors

- Complete movement audit trail

- Faster replenishment cycles

- Improved warehouse efficiency

- Better inter-branch coordination

The system enhances operational visibility and reduces stock-related confusion.

Common Stock Transfer Issues and Resolutions

Stock Not Updating

Possible causes:

- Goods Issue not completed

- Goods Receive not saved

- Permission restrictions

Verification of workflow completion resolves most issues.

Quantity Mismatch Between Branches

Possible reasons:

- Incorrect quantity entry

- Incomplete Goods Receive

- Previous stock adjustments

Regular reconciliation is recommended for accurate control.

Best Practices for Efficient Stock Movement

- Confirm correct branch selection

- Verify quantities before saving

- Maintain reference numbers for tracking

- Perform periodic stock reconciliation

- Avoid undocumented manual stock edits

Structured stock movement improves overall inventory management performance.

Related Topics

- Manufacturing Voucher – Convert raw materials into finished goods and update inventory automatically.

- Barcode Printing Label – Generate product barcode labels for faster billing and stock identification.

- Goods Dispatch Note – Document stock dispatched from warehouse or branch locations.

- Goods Receipt Note – Confirm stock received and update branch inventory accurately.

- Stock Take – Physical Inventory & Cycle Count – Perform physical stock verification and reconcile inventory differences.

Stock Transfer in O2VEND provides a systematic and controlled approach to branch-level inventory management.

By following the defined workflow — Create → Issue → Receive — organizations can maintain accurate stock records, prevent discrepancies, and ensure seamless internal inventory movement across all business locations.