Outward Route Configuration for GDN in O2VEND: Complete Setup Guide

What Is Outward Route Configuration & Why It Matters

Outward route configuration is the backbone of controlled warehouse dispatch in O2VEND. It determines whether your team can initiate goods shipment and controls the entire pick-pack-deliver workflow.

Key Benefits:

- Prevent unauthorized inventory deductions

- Streamline dispatch approvals

- Ensure accurate stock movement tracking

- Improve warehouse operational efficiency

How Location Routing Controls the "Initiate Goods Issue" Button

The Initiate Goods Issue button visibility depends entirely on your Location Outward Routes configuration.

Why this matters:

- Your dispatch location must have an active outward route

- Route permissions determine who can initiate shipments

- Branch-level routing logic controls button access

If the button isn't visible, check:

- Location configuration in Back Office

- Outward route mapping status

- User role and dispatch permissions

Pro Tip: Proper routing prevents unauthorized inventory transactions and ensures structured stock movement across your warehouse.

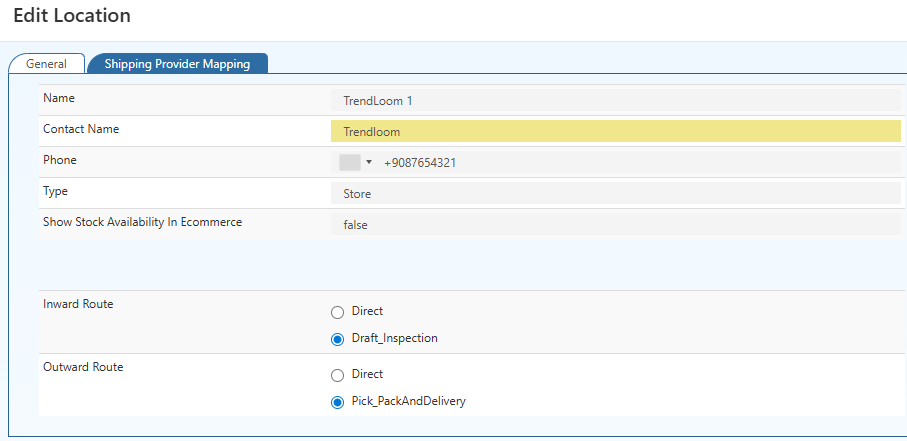

Configure Outward Route: Pick_PackAndDelivery Step-by-Step

The Pick_PackAndDelivery Route Explained

Setting your Outward Route to Pick_PackAndDelivery activates:

- ✅ Initiate Goods Issue button

- ✅ Structured Pick → Pack → Deliver workflow

- ✅ Real-time inventory control

- ✅ Approval-based stock deduction

How to Enable Pick_PackAndDelivery Routing

Follow these steps:

- Navigate to Back Office → Locations → Edit Location

- Find the Outward Route field

- Select Pick_PackAndDelivery

- Click Save Changes

Result: The Initiate Goods Issue button becomes immediately active.

⚠️ Important: Button availability is location-dependent. Ensure your selected branch has proper outward routing configured before initiating dispatch.

Complete Workflow: From Configuration to Dispatch

Step 1: Set Location Routing

Configure the location with Outward Route = Pick_PackAndDelivery

Step 2: Create a New GDN

Generate a Goods Dispatched Note in your system

Step 3: Select Dispatch Location

Choose the correct branch and click Initiate Goods Issue

Step 4: Access the Packages Tab

Review and manage package details, courier selection, and shipping labels

Step 5: Finalize & Approve

Confirm dispatch—stock reduces only after full approval

Outcome: Controlled workflow prevents premature stock deduction and maintains accuracy.

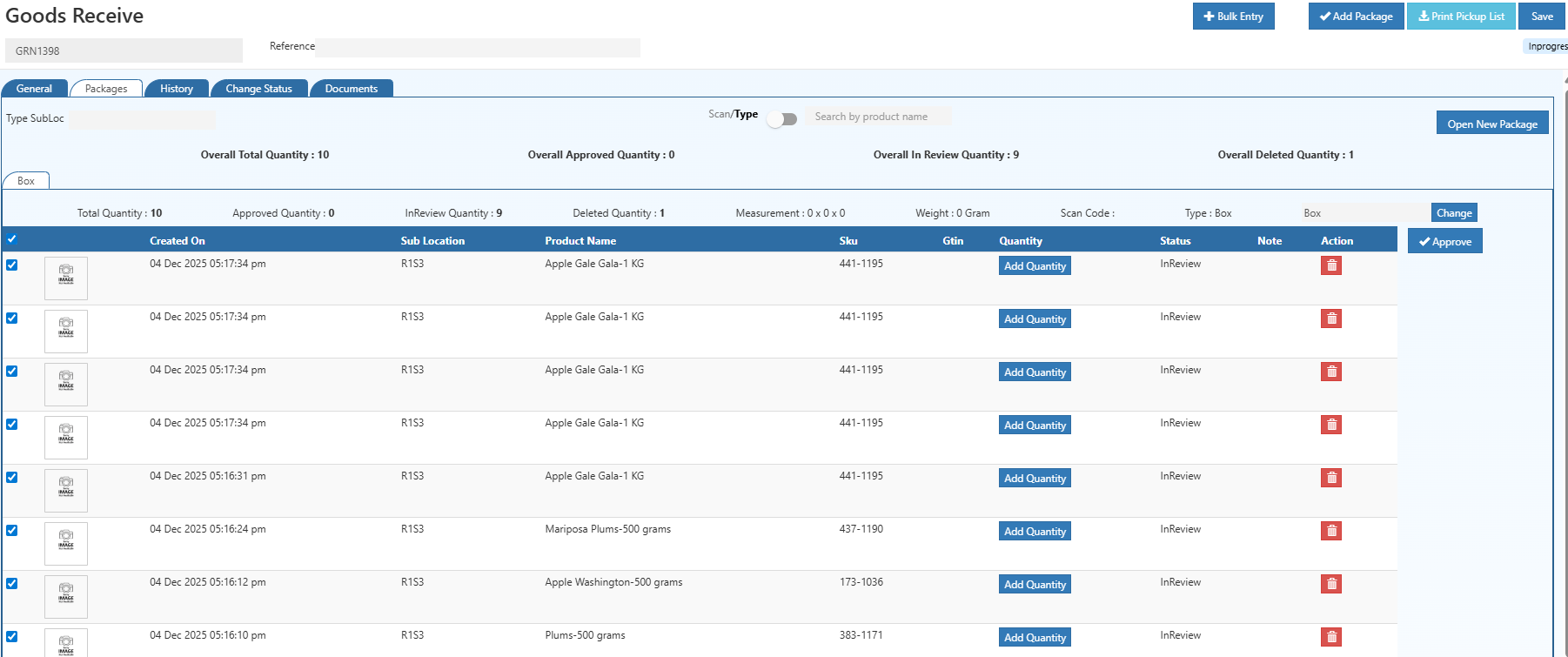

Packages Tab: Package-Level Control for Accurate Dispatch

The Packages Tab is your central hub for managing outbound shipments at the package level.

What You Can Do in the Packages Tab

- Create multiple packages per shipment

- Assign products to specific packages

- Enter weight and dimension details

- Enable COD (Cash on Delivery)

- Generate shipping labels

- Track courier handover status

Why Package-Level Management Improves Operations

✓ Reduces courier billing errors

✓ Prevents incorrect label generation

✓ Enables precise delivery tracking

✓ Strengthens audit compliance

✓ Improves freight cost accuracy

7-Step Package Verification Process

Step 1: Select or Create a Package

- Choose an existing package OR

- Click Initiate Goods Issue to create a new shipment unit

Each package represents one physical shipment (box, carton, pallet).

Step 2: Scan or Search Products

Use the Scan/Type toggle to add items:

- Scan Mode: Barcode scanning for speed and accuracy

- Type Mode: Manual search by product name or SKU

Recommendation: Scan mode reduces errors in high-volume warehouses.

Step 3: Review the Product List

Verify all added items including:

- Date & time added

- Sub-location (rack/shelf)

- Product name & SKU

- Quantity status

Step 4: Add Quantity Per Item

- Click Add Quantity for each product

- Update dispatched amounts

- Prevent over-dispatch errors

Step 5: Verify Item Accuracy

Before approval, confirm:

- ✓ Correct product selected

- ✓ Accurate quantity entered

- ✓ Correct sub-location identified

- ✓ Status shows InReview

Step 6: Remove Incorrect Items

If errors occur:

- Click Delete on incorrect entries

- Re-scan or re-add correct products

- Prevents shipment mismatches

Step 7: Approve & Finalize

- Select verified items

- Click Approve

- Items exit InReview status and become part of final package

GDN vs Invoice vs Delivery Challan: Key Differences

Understanding these documents prevents workflow confusion and ensures proper processing.

| Document | Primary Purpose | Impact |

|---|---|---|

| GDN | Records warehouse dispatch | Reduces inventory stock |

| Invoice | Billing and payment collection | Affects accounting/revenue |

| Delivery Challan | Goods transportation record | Supports physical delivery |

Quick Rule: GDN = Inventory reduction | Invoice = Billing | Delivery Challan = Transportation

Common GDN Questions (FAQ)

Q: What does GDN stand for?

A: Goods Dispatched Note—the official record that goods left your warehouse.

Q: How does GDN affect inventory?

A: GDN triggers real-time stock reduction and maintains accurate warehouse records.

Q: Is GDN the same as an invoice?

A: No. GDN confirms dispatch; invoices handle billing. Both are essential but separate documents.

Q: Why should I use the Packages Tab?

A: It prevents shipping errors, reduces courier mistakes, and maintains audit trails.

Summary: Best Practices for GDN & Outward Routes

✅ Configure all locations with Pick_PackAndDelivery routing

✅ Use the Packages Tab for professional logistics management

✅ Verify items before dispatch approval

✅ Maintain proper GDN, Invoice, and Delivery Challan documentation

Result: Accurate inventory, reliable shipments, and complete audit compliance.